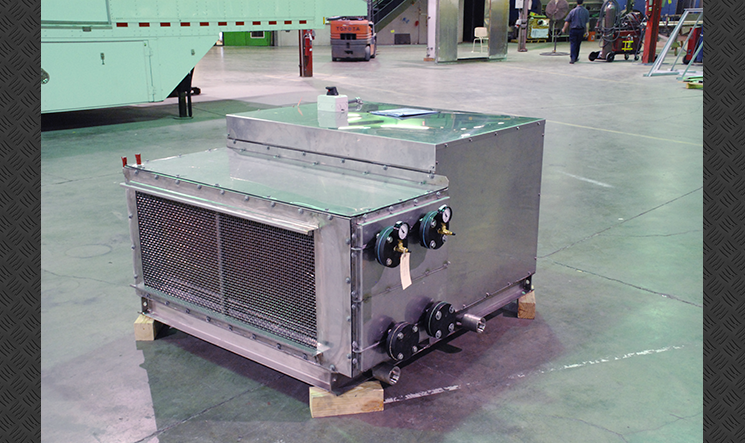

Air Handlers & Fan Coils

Ellis & Watts designs, qualifies, manufactures, and tests custom air handlers (AHUs) and fan coils to provide conditioned air for mission-critical comfort, environmental, and process environments where meeting design temperature, humidity, and/or sound requirements are crucial.

Ellis & Watts can provide AHUs and Fan Coils with the following features and capabilities - CLICK TO SEE FULL LIST

- varying housing thicknesses and insulation types

- variety of fan types, configurations, and sizes

- wide range of supply air temperatures

- analog, relay-based controls to address qualification, cyber security, or EMI/RFI concerns or digital control systems

Specific capabilities for AHUs and Fan Coils include - CLICK TO SEE FULL LIST

- flexible dimensions and component selection to optimize performance, efficiency, ease of service, and life-cycle cost

- operation in extreme ambient temperatures

- up to 60 inches w.g. static pressure

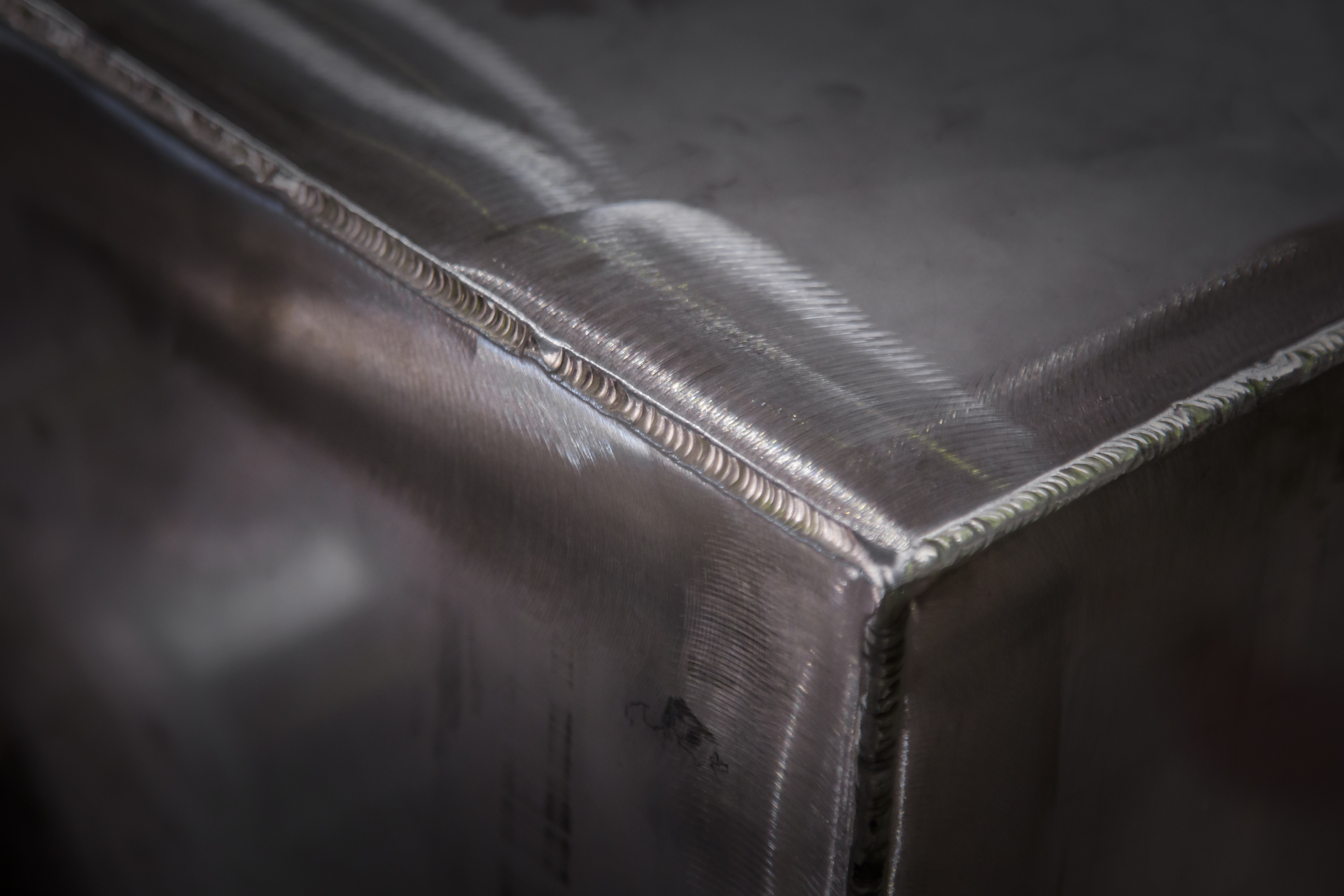

- wide choice of materials of construction available to optimize structural integrity, corrosion resistance, weight, and cost

- stringent air leakage requirements

- seismic qualification per IEEE 344

- environmental qualification per IEEE 323

- various power supply, piping and control options

- designs for hazardous duty applications (explosion proof)

- EMI/RFI suppression and verifications testing

- portable or mobile designs, including shock and vibration isolation

- factory performance testing at full and part-load conditions to document compliance and assure proper operation

- self-contained packaged or split-system designs

- modular construction to address on-site transportation, rigging, and installation constraints

Ellis & Watts understands that some projects require strict code compliance and has the demonstrated ability to conform to the following codes, among others - CLICK TO SEE FULL LIST

- ASME NQA-1

- 10CFR50 Appendix B

- Heat Exchangers to ASME Section VIII or ASME Section III

- Coils (Refrigerant & Electric) to ASME AG-1 Section CA

- Fans to ASME AG-1 Section BA

- Motors to ASME AG-1, IEEE 323, IEEE 334, IEEE 344, and NEMA MG-1

- Motor wiring to IEEE 383

- Motor insulation to IEEE 117

- Filters to ASME AG-1 Section FB & FC

- Filter Mounting Frames to ASME AG-1 Section FG

- Dampers to ASME AG-1 Section DA

- UL 555 for Smoke and Fire Dampers

- Damper Actuators to IEEE 382

- Housing to ASME AG-1 Section HA

- Instruments to ASME AG-1 Section IA

- Compliance to IEEE 7-4.3.2 Standard Criteria for Digital Computers in Safety Systems of Nuclear Power Generating Stations

- Compliance to IEEE 603 Standard Criteria for Safety Systems for Nuclear Power Generating Systems

- Compliance to IEEE 1012 Standard for Software Verification and Validation

Past projects in which Ellis & Watts successfully met stringent air handling system compliance requirements include - CLICK TO SEE FULL LIST

- V.C. Summer NPP – USA

- Vogtle NPP – USA

- Cernavoda NPP – Romania

- MOX Fuel Fabrication Facility – USA

- Palisades NPP – USA

- US Army